RockRidge Abrasives, a subsidiary of GNPGraystar, was created by a collective of abrasive specialists who wanted to supply our customers with high-quality abrasives that we have hand-selected and thoroughly tested.

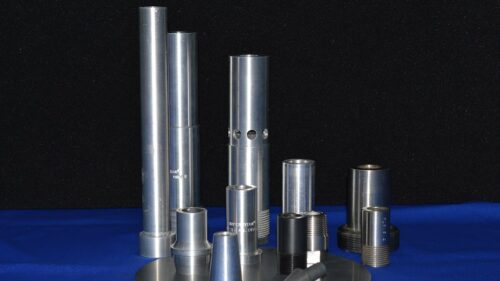

Our product line includes Garnet & Waterjet Cutting Parts for blasting and waterjet cutting applications, Glass Beads, Low Carbon Steel Shot, Coated and Non-Woven Abrasives, Vibratory Abrasives, Aluminum Oxide, and other specialty materials.

We are involved face-to-face in the industry and constantly evolve our knowledge and products to best serve our customers’ needs and to improve their processes.

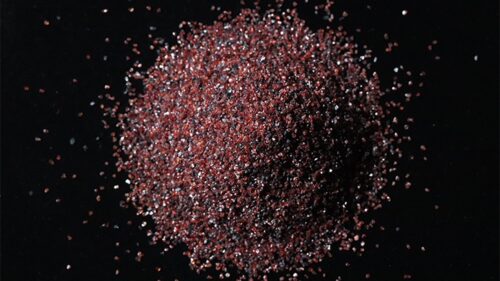

Garnet

RockRidge ensures that their Premium Garnet is a non-ferrous, 100% natural mineral abrasive. Their garnet is environmentally inert and poses no health or environmental concerns. Garnet also has no Beryllium content and no heavy metal content. Therefore, there are no concerns with disposal unless garnet is used on a heavy metal or hazardous coating.

Garnet’s average Mohs hardness is 7.5-8.0 making it ideal for both surface preparation and waterjet applications.

Blasting with garnet results in a safe, cost-effective cleaning and surface preparation operation. Its durability offers multiple turns, leading to savings on consumption, shipping, and disposal.

Garnet has the cutting ability to reach bare metal, removing corrosion or coatings. It can achieve mil profile finishes for most coating applications.

Garnet is ideal for use on ferrous and non-ferrous materials. Other types of media may present cross-contamination concerns on aluminum and stainless steel.

Glass Beads

RockRidge Glass Bead media breaks down at a slow rate and can survive multiple impacts. This allows for continuous recycling and extended blasting time. Glass beads are chemically inert and will not leave any residue on the surface of the workpiece.

Blasting with glass beads allows the user to clean workpieces quickly without any significant metal removal. Due to the shape of the glass beads, they clean, finish, peen, and deburr. That four-step process provides a controlled, unique, and clean surface finish.

Glass beads can be used in many peening applications. It is also an excellent choice for cosmetic surface finishing.

Typical Physical Characteristics:

- Specific Gravity: 2.4 – 2.6

- Bulk Density: 1.4 – 1.6 g/cm 3

- Micro Hardness: ≥ 600 kg / mm 3

- Roundness: ≥ 90%

Glass beads meet all OSHA and ISO 11126-10:200 requirements and do not contain free silica. RockRidge Glass Beads are available in the range of mil-spec sizes: #3 – #13

Qualities of Glass Beads:

- Round abrasive media that is reusable and will produce a satin finish

- For cleaning, peening, and cosmetic finishing where stock removal must be minimized

- A wide range of sizes allows smooth to more textured finishes and are excellent for ferrous and non ferrous surfaces

- Glass beads are also excellent for light to medium peening of metal parts to reduce fatigue

- Glass beads are widely used on aluminum and stainless steel

Steel Shot

RockRidge proudly sells low carbon steel shot to our customers.

COMING SOON – RockRidge will soon offer Steel Grit!

Check back soon for more information.

The service life of low carbon steel shot is typically 20% longer than its high carbon steel equivalent. RockRidge low carbon steel shot, with its long life and high hardness, gives excellent performance in most blast cleaning applications including:

- the removal of sand from castings

- removal of scale and rust from steel

- deburring of machined parts

- general surface preparation of metal parts

RockRidge steel shot is ideal for use in foundries, forges, steel mills, rolling mills, machine shops, in automobile and aircraft industries as well as in the structural steel industry.

RockRidge Steel Shot is available in two packaging options: forty 50 lb. polythene bags on a wooden pallet with a box top or 55-gallon steel drums on special drum pallets.

Aluminum Oxide

RockRidge Aluminum Oxide comes in either Brown-Fused or White-Fused. Brown-Fused Aluminum Oxide is a standard blasting abrasive while White-Fused Aluminum Oxide is a high-purity abrasive for when the application requires minimal foreign contamination or higher friability.

RockRidge Aluminum Oxide is graded to micro or macro grit exacting standards. Aluminum Oxide is an abrasive that can be repeatedly circulated.

Aluminum Oxide is suitable for wet or dry surface preparation, cleaning, deburring, and cutting of various metals, ceramics, glass, wood, rubber, plastic, stone, and composite materials.

Qualities of Aluminum Oxide:

- Extremely hard, sharp, and durable abrasive

- Angular shape and fairly high bulk density will produce a matte surface finish

- Abrasive is generally reusable many times because of its hardness and durability.

- Anchor pattern creation prior to coating or bonding

- Rust, scale, or other tough contaminant removal

- Application must tolerate some metal removal

- Used for grinding and lapping as well as abrasive blasting

- Is a good choice for etching

Specific Qualities of White-Fused Aluminum Oxide:

- Tough cleaning and surface etching application that have a very low tolerance for iron residue

- Extremely hard, sharp abrasive

- Similar to brown-fused, but manufactured for an extremely low iron content

- More friable than brown aluminum oxide

Coated and Non-Woven Abrasives

RockRidge also offers Coated & Non-Woven Abrasives such as:

- Resin-Fiber Discs

- Flap Discs

- Sanding Discs

- Quick-Change Discs

- Hand Pads

For more information, please visit RockRidge.