GNPGraystar has a very well-equipped laboratory for detailed examination of our products. We can analyze Particle Sizing (both for macrogrits and microgrits), Particle Shape, Bulk Density, Specific Surface Area, Moisture & LOI, Magnetics, Viscossity, Hall Flow, Angle of Repose, Crushing Strength, and more.

Our lab is available for analyzing your products as well. We offer these services on a toll basis with quick turnaround time.

Contact us to learn more on how we can evaluate your raw materials.

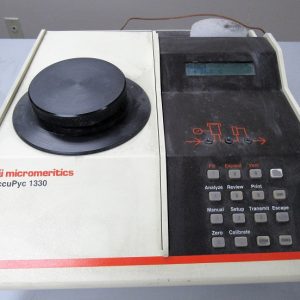

Through the use of our Micromeritics Gemini Surface Area Analyzer, we can measure the specific surface area of your powder.

Through the use of our Micromeritics Gemini Surface Area Analyzer, we can measure the specific surface area of your powder. We have an automated moisture analyzer that we can use to rapidly measure the moisture in grains and powders. We also have drying and sintering furnaces that allow us to measure Loss on Ignition (LOI).

We have an automated moisture analyzer that we can use to rapidly measure the moisture in grains and powders. We also have drying and sintering furnaces that allow us to measure Loss on Ignition (LOI). With the use of our Buck Analyzer (Micromeritics MA-1040 Magnetic Analyzer) we can measure the percent of free magnetics (iron) in your or our grains and powders.

With the use of our Buck Analyzer (Micromeritics MA-1040 Magnetic Analyzer) we can measure the percent of free magnetics (iron) in your or our grains and powders.