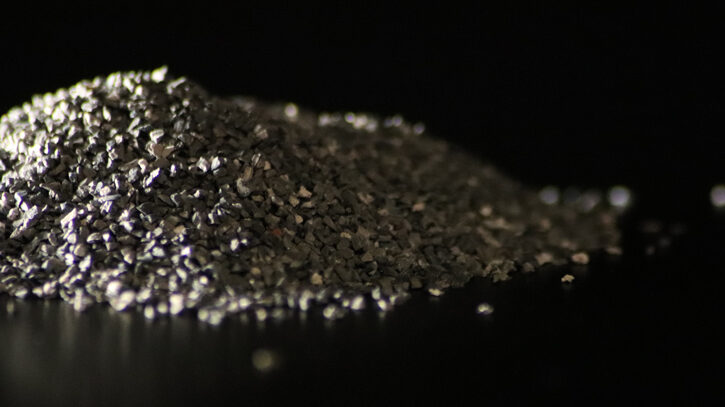

GNPGraystar’s Aluminum Zirconia products are hard, very tough, sharp abrasives. They are available in both 25% and 40% zirconia content and produced by fusing zircon sand with alumina at about 1900°C.

Alumina Zirconia 25% is used primarily for producing large grinding wheels for foundry snagging and track grinding. It is also an excellent blasting material for granite and other materials where long life is required, as well as in some refractory applications.

Alumina Zirconia 40% is used for both coated abrasive products and organic bonded grinding wheels.